Our Products

Description:

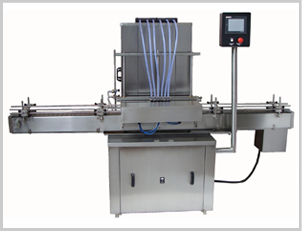

“GMP’s” Automatic VISCOFILL Liquid Bottle Filling Machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine. Machine works on VOLUME=TIME TECHNOLOGY AND SPEED=FLOW RATE. The unit is made compact, versatile and S.S. body. “No container-No filling” system arrangement is standard features of the machine. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body.

Model |

|

|

|

|

|

Output/Hour* |

Up to 3000 Nos. |

Up to 5000 Nos. |

Up to 7200 Nos. |

Up to 9000 Nos. |

|

Direction of Movement |

Left to Right |

Left to Right |

Left to Right |

Left to Right |

|

Number of head/Nozzle |

2 Nozzles |

4 Nozzles |

6 Nozzles |

8 Nozzles |

|

Fill Size |

5 ml to 500 ml |

5 ml to 500 ml |

5 ml to 500 ml |

5 ml to 500 ml |

|

Electric Specification ** |

Filling Section |

0.7 KW / 415Volts / 50 Hz. X 2 Nos. |

3.00 KW / 415Volts / 50 Hz. X 4 Nos. |

3.00 KW / 415Volts / 50 Hz. X 6 Nos. |

3.00 KW / 415Volts / 50 Hz. X 8 Nos. |

Conveyor |

0.5 HP / 415 Volts / 50 Hz. |

0.5 HP / 415 Volts / 50 Hz. |

0.5 HP / 415 Volts / 50 Hz. |

0.5 HP / 415 Volts / 50 Hz. |

|

Height of Conveyor ** |

860 to 910 mm Adjustable. |

860 to 910 mm Adjustable. |

860 to 910 mm Adjustable. |

860 to 910 mm Adjustable. |

|

Container Neck Diameter** |

Minimum 25 mm , Maximum 57mm*** |

|

Container Size** |

Round Shape |

Ø 28 mm to Ø 100 mm |

Flat / Square |

50mm to 125 mm (Length) |

|

* Depends on Container size, fill size, Neck diameter of container, nature of liquid & operator etc.

** We can supply as per customer requirements.

• No change parts require.

• Individual volume control for all syringes.

• Different speeds can be set, depending on fill volume and foaming nature of material

• Body covered with SS sheet.

• All contact parts silicon tubing / S.S.316.

• A unit to fill variety of liquid and can be used for various type of containers.

• No dripping or last drop problem

• No contamination

• No maintenance required

• No bottle no filling system.

• Facility provided for the fine tuning of the volume

• Inbuilt protection against over current, voltage fluctuation, short circuit in ac frequency drive.

• Ideal for aseptic, sheer sensitive, viscous, and corrosive liquids also.

Electrical supply : Three Phase + Neutral + Earthing

Electrical load : 1.5 Kw

Air Pressure: Minimum : 6 bar pressure 0.5 CFM