HVAC & Clean Room & MEP Service

Products & Services || HVAC & Clean Room & MEP Service

HVAC Solution

One of the key considerations for plant design is an effective and efficient solution to ensure the right air pressure, humidity, temperature and cleanliness is maintained. Our 25 year’s plus experience helps us define the best in class solution in budget and as per regulatory requirements.

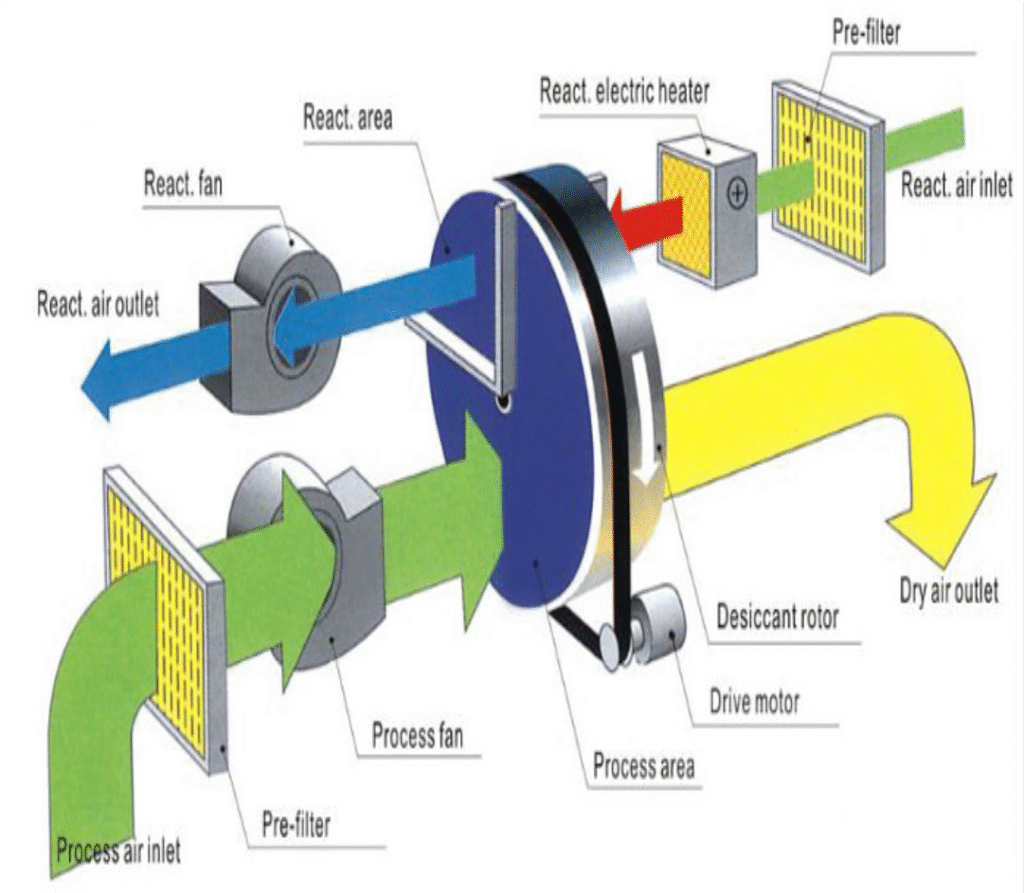

Dehumidification

GMP has a wide range of industrial dehumidifiers catering to the varied application needs across diversified industries. The dehumidifiers are reliable, energy-efficient and cost effective.

We can easily maintain RH up to 25 to 30% with the help of Dehumidifier.

Working Principle

- Maintains and Provides Cool, Dry, Sterile air

- Uniform Drying time

- Reduces drying time from several days to few hours

- Maximise Production time by eliminating costly down time due to poor air quality

- Maintains a clean controlled temperature and humidity energy efficient reduces utility consumptions

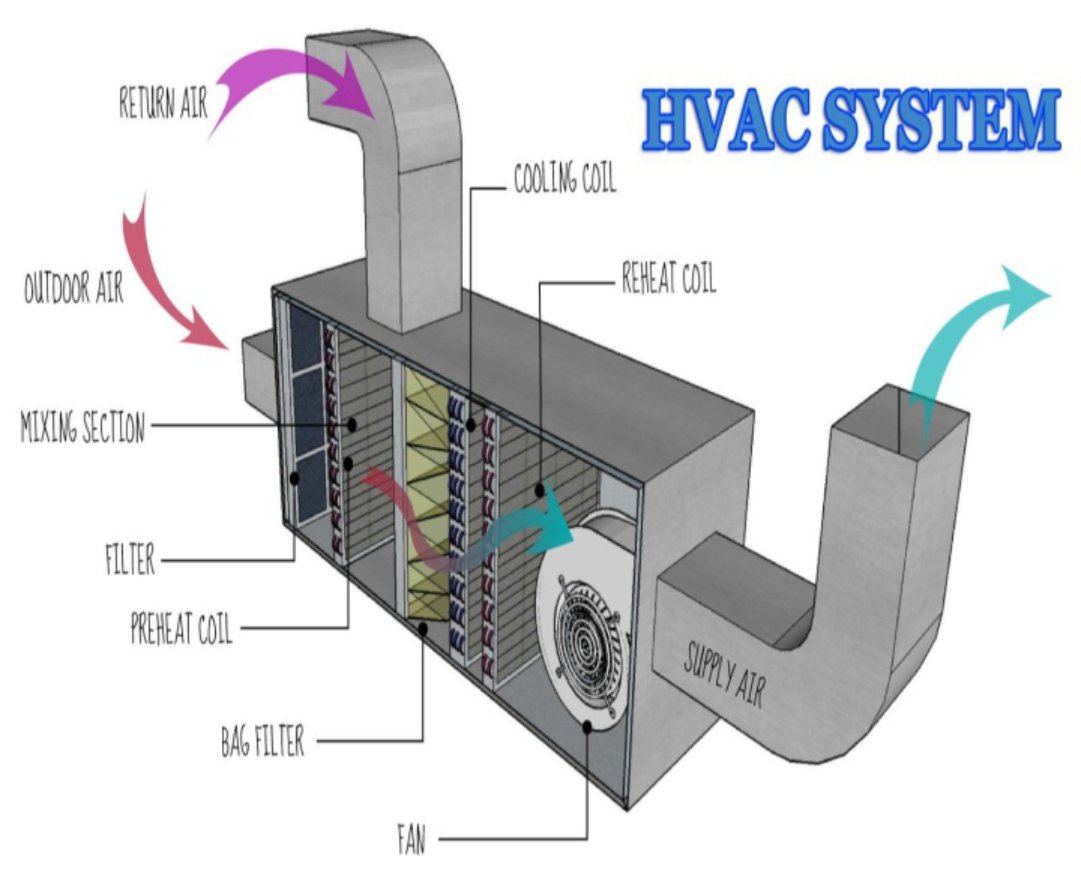

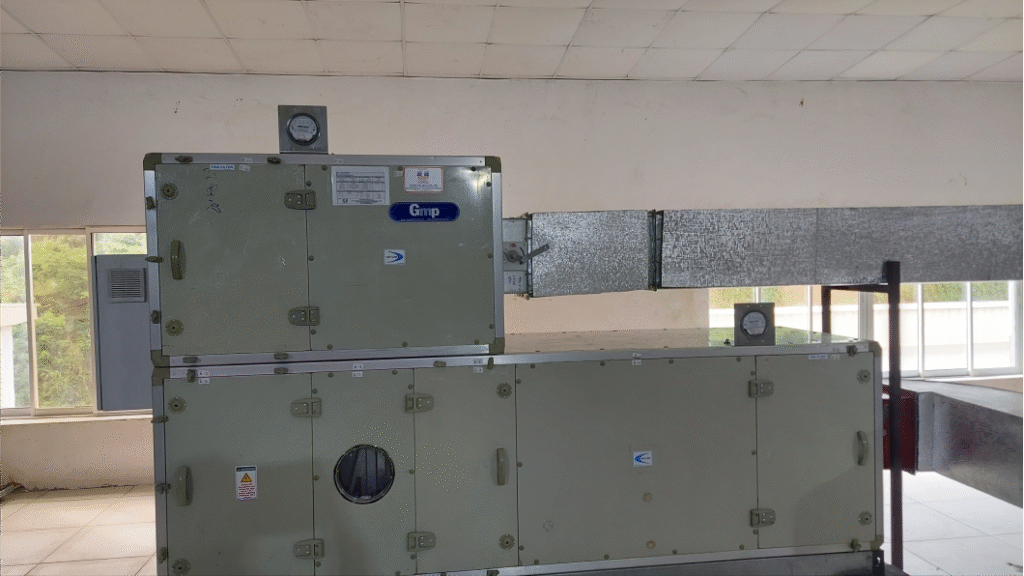

Air Handling Unit

An Air Handling Unit (often abbreviated to AHU), is a device used to condition and circulate air as part of a heating, ventilation, and cooling (HVAC) system. An AHU is usually a large double skin metal box containing a blower, heating and cooling elements filter(s) racks or chambers, sound attenuators, and dampers. AHU will be connected to a ductwork ventilation system that distributes the conditioned air through the building and returns itto the AHU.

Vrf/Vrv

Filtration

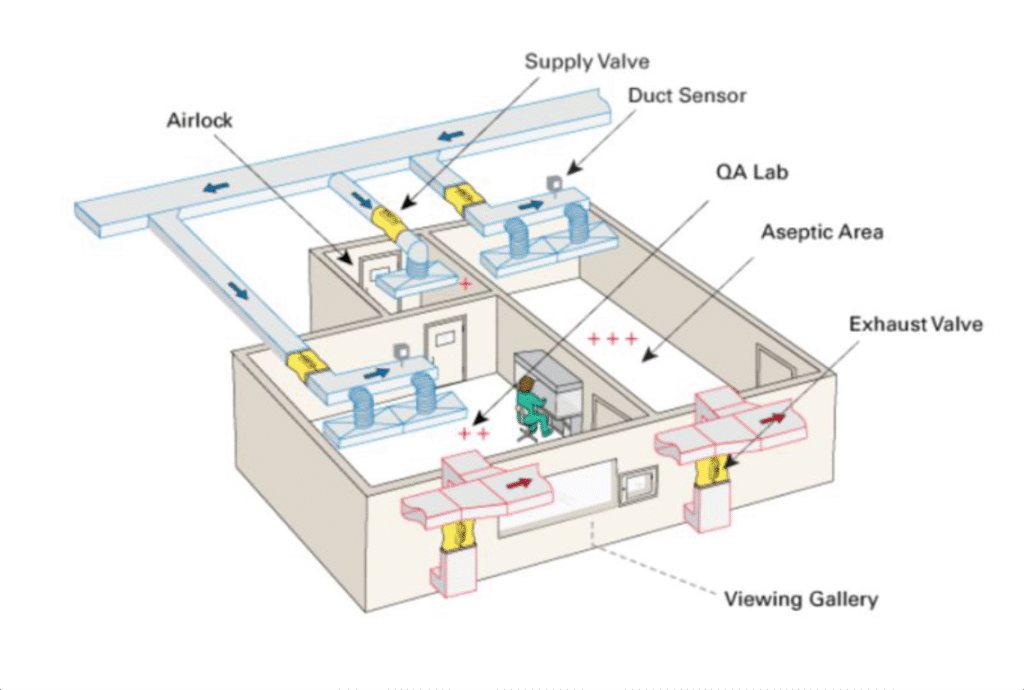

What is Cleanroom?

A room in which concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction, generation and retention of particles and microbes inside the room and in which other relevant parameters, e.g. temperature, humidity and pressure are controlled as necessary

Cleanrooms are classified To put the size of a micron into Pressures must also be kept from ISO 1 to ISO 9. These perspective; a human hair is static and over the atmospheric standards are based on the approximately 75 microns thick.

A pressure in order to prevent number of particles allowed typical room in a home would infiltration into the New per unit volume of air within contain more than 10,00,000 air inputs must be balanced the space. The physical size of particle of 0.5 um and above, this along with the release of air a particle is measured in a unit roughly equates to a class ISO 9 from the room to keep the called as a micron (ym). cleanroom. pressure value maintained. Clean rooms are used in many different industries in addition to Pharmaceutical, Healthcare, Processing, including Cosmetic, FMCG, military, aerospace, and computer manufacturing.

- EU3/EU4 level filters.

- EU9 pocketfilters in atthe entrance.

- EU14 box filtering from the ceiling.

- Airleaves the environment through wall grille.

- EU3/EU4 level filters.

- EU8 pocketfilters in atthe entrance.

- EU14 box filtering from the ceiling.

- Airleaves the environment through wall grille.

- EU3/EU4 level filters.

- EU8 pocket filters in at the entrance.

- Eu13 absolute filters in at exit.

- Distribution of filters from the ceiling.

- Air leaves through ceiling grille.

- Features finely permeable fabric channels.

Modular Cleanroom -Wall Partitions & Ceiling Panels

Supply and Installation of Production and Packaging Machineries